Page 56 - I want to create content about steel!

P. 56

SUMMARY ③ Korea Iron & Steel Association

Iron ore becomes steel

How do you take ore that is buried in the mine and create a steel product? Let's take a look at the process by which steel is

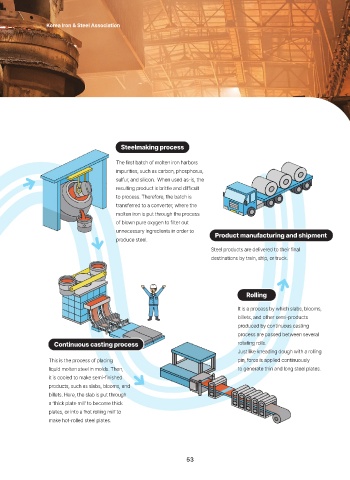

made at an integrated mill. Steelmaking process

The first batch of molten iron harbors

impurities, such as carbon, phosphorus,

Storage of raw materials sulfur, and silicon. When used as-is, the

resulting product is brittle and difficult

The process brings iron ore to process. Therefore, the batch is

and bituminous coal mined

transferred to a converter, where the

from Australia and Brazil by

molten iron is put through the process

boat. Then, they are stored.

of blown pure oxygen to filter out

unnecessary ingredients in order to

Product manufacturing and shipment

produce steel.

Ironmaking process Steel products are delivered to their final

destinations by train, ship, or truck.

It is a process of making molten iron

by feeding into the furnace small

pieces of iron ore (sintered ore) and

coke that have been pre-treated

Rolling

through ‘sintering’ and ‘coking.’

When air heated to 1,200℃ is blown It is a process by which slabs, blooms,

into the bottom of the furnace, coke, billets, and other semi-products

Pre-treatment of Raw Materials which acts as the fuel, is oxidized produced by continuous casting

by the heat. At this time, the coke process are passed between several

Sintering generates carbon monoxide, which Continuous casting process rotating rolls.

Through this process, the varying components removes the oxygen attached to iron Just like kneading dough with a rolling

of the iron ore are made more consistent and the ore. Through this chain of chemical This is the process of placing pin, force is applied continuously

ore is shaped into sizes more appropriate to feed reactions, iron ore becomes ‘molten liquid molten steel in molds. Then, to generate thin and long steel plates.

into the furnace. The outcome of this process is iron,’ which flows out of the furnace. it is cooled to make semi-finished

called ‘sintered ore.’ products, such as slabs, blooms, and

billets. Here, the slab is put through

Coking

a ‘thick plate mill’ to become thick

This is the process of heating coal

plates, or into a ‘hot rolling mill’ to

to around 1,000℃ to create solid fuel.

make hot-rolled steel plates.

Coke acts as a reducing agent that melts raw

A piece of A piece of

materials in a furnace and separates oxygen

knowledge knowledge

from iron ore.

52 53